Our specialists help to realize the desired idea

Quick solutions for every task. We have a fast and cost-effective approach to manufacturing high-precision details in an array of engineering-grade materials. Be it the production of individual CNC components or larger series.

- CAM programming

- Serial production

- Cutting processes

- Surface treatment

- Prototyping

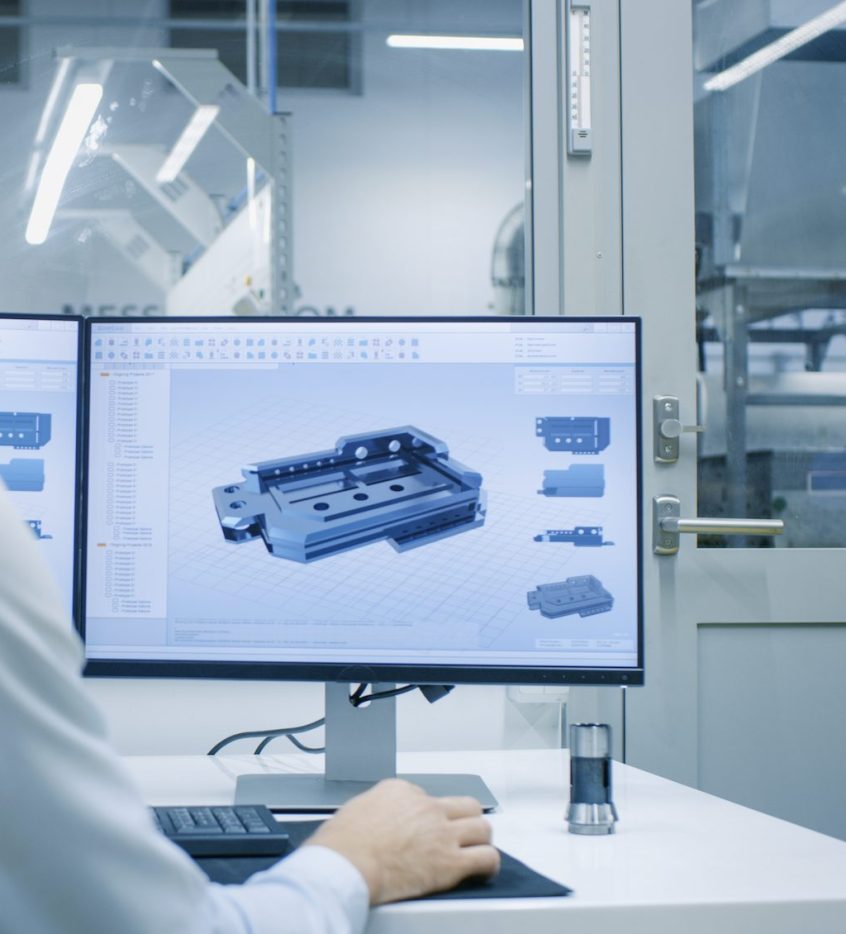

CAM programming

We use CAM manufacturing software to automate processes on CNC machining tools. With the help of CAM software, we integrate the designs into the machines, add processing technology (cutting speeds, feeds, rotation frequencies), and then the CNC machine can produce the desired part according to the design and technology. Ask more

Serial production

With CNC machining, you can meet a wide range of your product development needs. We manufacture high-precision CNC details for partners in various fields. We provide products from a single prototype to large series, from single components to more complex sets. In cooperation with partners, we also offer customers the cutting, thermal, and surface coating processes. Ask more

Cutting processes

We offer CNC milling and CNC turning capabilities to realize your project. 3-axis, 4-axis, and 5-axis CNC milling machines are used to produce high-precision details. ISO9001 quality system certificate ensures the high quality of our products. Ask more

Surface treatment

Surface finishing is the final stage of the CNC machining process. We can remove aesthetic defects, improve the product's appearance, provide additional strength and durability, and adjust electrical conductivity with surface treatment. Ask more

Prototyping

We make prototypes for most areas of technology. A prototype is necessary to verify product functionality in almost all industries where precision machining is used. Contact us for more details. Ask more

Our selection includes all common materials

We have extensive experience processing various materials: plastics, composites, aluminum, non-ferrous alloys, stainless steel, cast iron, and special steel. In cooperation with partners, we offer customers most of the cutting, thermal, and surface coating processes.

- Aluminium

- Steel

- Plastic

- Brass

- Copper

- Titanium

- Stainless steel